(1). Scanning Electrical Mobility Spectrometer (SEMS)***掃瞄式氣膠粒徑分佈監測儀***

BMI has developed an advanced Windows®-based real time software with a

graphical user interface to simplify the SEMS operation.

The core software enables rapid time scanning of the spectrometer voltage to

select a broad size range of particles in time sequence, allowing the

condensation particle counter to measure the number size distribution - how

the concentration of particles varies with particle size. This is a fundamental

measurement in the field of air quality research and industrial nanoparticle

monitoring.

The measurement accuracy is enhanced through a key innovation in the

scanning software that addresses the effects of desmearing, multiple charging,

and the DMA transfer function.

(2). Mixing Condensation Particle Counter (MCPC) ***快速混合型微粒計數器***

The MCPC grows particles rapidly through the turbulent mixing of particle and butanol-saturated flows. Benefits include:

• Ultra-fast response

• Detects particles as small as 5 nanometers

• Extremely compact and light-weight

(3). Humidified Tandem Differential Mobility Analyzer (HTDMA) ***增濕型氣膠成長因子監測儀***

The HTDMA allows size-resolved measurements to be made of the water

uptake properties of aerosols. This information is critical for understanding how

particles act as cloud condensation nuclei and how particles grow and deposit

within the human respiratory system. HTDMA data have found important

applications in research on the climate impacts of aerosols.

Fully automated and easy-to-use software allows the user to configure the

HTDMA to step through a pre-selected series of monodisperse dry particle sizes

with multiple RH’s tested at each size. The cycle may be repeated automatically

for as long as desired.

A built-in calibration system that introduces known chemical composition

particles into the HTDMA may be purchased as an option to validate operation.

(4). Particle into Liquid Sampler Head (Model 4000) ***水洗式氣膠收集器PILS***

The economical PILS Head and Steam Generator is ready to interface with your liquid handling system and collect samples for analysis of multiple water soluble inorganic

or organic species.

Key Features:

Quantitative sampling efficiency and field tested

Rapid water soluble composition data

Easily integrated with user’s Ion Chroma-tography or other analysis system

Suitable for ground based sampling or laboratory experiments

(5). AEROSOL GENERATION SYSTEM ***氣膠產生系統***

Our atomizer-based Aerosol Generation System produces particles of known chemical composition and diameter size range. Features include: • Syringe pump with a broad range of liquid flow rate control • In-line dryer to remove particle-bound water • Dilution chamber for diluting high concentration atomizer output

(6). Aerosol Neutralizer Body ***氣膠電荷中和器***

Key Features:

Sample flow rates: 1-5 lpm

Total particle concentrations: up to 50,000/cc

Charge neutralizer performance has been validated against other commercial neutralizers

Structure: Stainless steel tubing with high vacuum brazed construction

Compact Design: 9”L x 1.25” diameter

Easy disassembly for cleaning and/or Polonium-210 source installation

Design can be easily adapted for mounting of other components (heaters, vapor sources, chillers, EM grids)

(7). Impactors ***衝擊式微粒粒徑篩選器***

Impactors are designed for different particle diameter cut sizes and various flow rates.

Our Impactors may be purchased with or without differential pressure sensors to

measure air low and to provide a warning of jet clogging.

(8). Laminar Flow Elements (LFE) ***層流板式流量量測元件***

Laminar Flow Elements (LFEs) are designed to measure flow rates between 0.03 and 20 lpm.

LFEs may be purchased with or without differential pressure sensors.

(9). Two-Way Flow Splitters ***一對二分流管***

Our Two-Way Flow Splitters are useful for careful division of particle-laden sample

flows. Each consist of 2” long legs and a 45° angle between the two exit tubes.

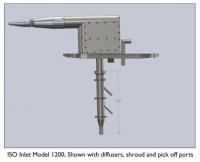

(10). Isokinetic Inlet System ***等動力採樣入口系統***

Inlets are offered with or without isokinetic flow control, where the sample flow rate is automatically controlled to match the ambient air speed.

Performance is validated through wind tunnel testing and computational fluid dynamics modeling.

Key Features:

Fully automated, hands-off operation

Transmission efficiency > 95% for particle diameters <6µm

Wind tunnel tested and validated

Inlet manifold designed to suit customer’s sampling needs

Aerodynamic, twin-diffuser prevents turbulent boundary layer separation

Removal of diffuser turbulent boundary layer through passive pumping

Proper accounting for attack angle through flexible mounting design

Low power blower to draw and actively control 150 lpm sample flow

(up to 50 lpm of air flow for instruments)

Sample pick-off ports for a user-specified number of instruments

De-Iced Diffusers and inlet aerodynamic shroud

Pitot tube for ambient velocity measurements and isokinetic flow control

Flow rate, pressure and temperature measurements of sample flow

Integrated data system to control operation, record all parameters and provide 1 Hz serial output data stream

Control electronics, keyboard, mouse & monitor conveniently packaged into two rack mountable enclosures

Inlet control software

(11). Counterflow Virtual Impactor Inlet System ***逆向流式虛擬衝擊器***

The CVI inlet is offered with automatic flow control, where the cloud droplet cut size is kept constant by changing the counterflow rate. Performance is validated through wind tunnel testing and computational fluid dynamics modeling.

Key Features:

Fully automated, hands-off operation

Droplet cut sizes between 5 and 40µm

Wind tunnel tested and validated

Inlet manifold designed to suit customer’s sampling needs

30 lpm of aerosol sample flow available to instruments

Counterflow rate software adjustable between 30 and 60 lpm to vary cloud droplet cut size

Ground-based operation possible using integrated wind tunnel

Proper accounting for attack angle through flexible mounting design

De-Iced inlet aerodynamic shroud

Pitot tube for ambient velocity measurements

Flow rate, pressure and temperature measurements of sample and add flows

Low power blowers to draw and actively control the 30 lpm sample flow and 60 to 90 lpm add flow

Integrated data system to control operation, record all parameters and provide 1 Hz serial output data stream

Control electronics, keyboard, mouse & monitor conveniently packaged into two rack mountable enclosures